- Monday Closed

- Tuesday 09:00AM - 06:00PM

- Wednesday 09:00AM - 06:00PM

- Thursday 09:00AM - 06:00PM

- Friday 09:00AM - 06:00PM

- Saturday 09:00AM - 02:00PM

- Sunday Closed

2024 Husqvarna TE 150 LIGHT WOODS FUN CASH REBATED PRICE $9299 PLUS HST

Powered by an all-new, lighter engine and equipped with Throttle Body Injection (TBI) for the very first time, the TE 150 offers improved torque and is expertly assembled with the latest technical innovations to deliver best-in-class performance. Setting a new standard for 2-stroke engine development, this small capacity model is incredibly versatile and highly capable in the hands of both beginners and seasoned racers alike. New, WP XACT suspension with enduro-specific settings offers advanced damping for enhanced handling and comfort across the roughest terrain. With a distinctive and fresh new look inspired by the Swedish roots of the brand, the TE 150 is the most complete, lightweight 2-stroke enduro machine on the market today.

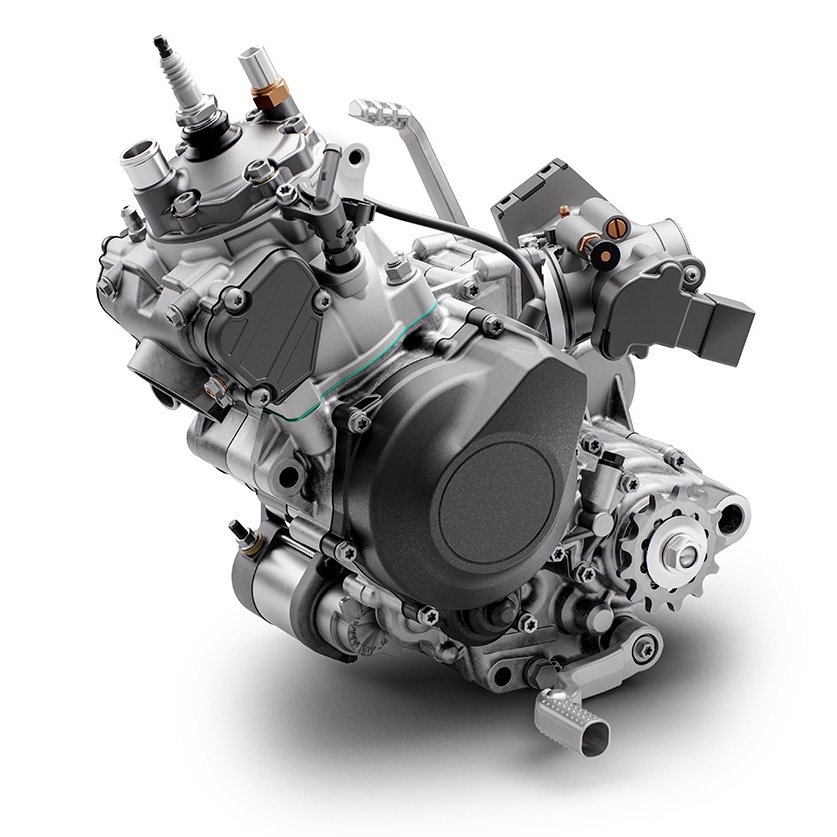

Engine

The TE 150 has inherited the same fuel-injected technology from the bigger TE 250 and 300. This adds the convenience of a 4-stroke engine by eliminating the need to premix fuel or adjust jetting for altitude. The engine also uses specific shaft arrangements, which are designed to harness the rotating mass of the engine for nimble handling. This, among other developments, makes it a lightweight and compact engine providing usable enduro-specific power while maintaining the low-cost maintenance of a 2-stroke. |

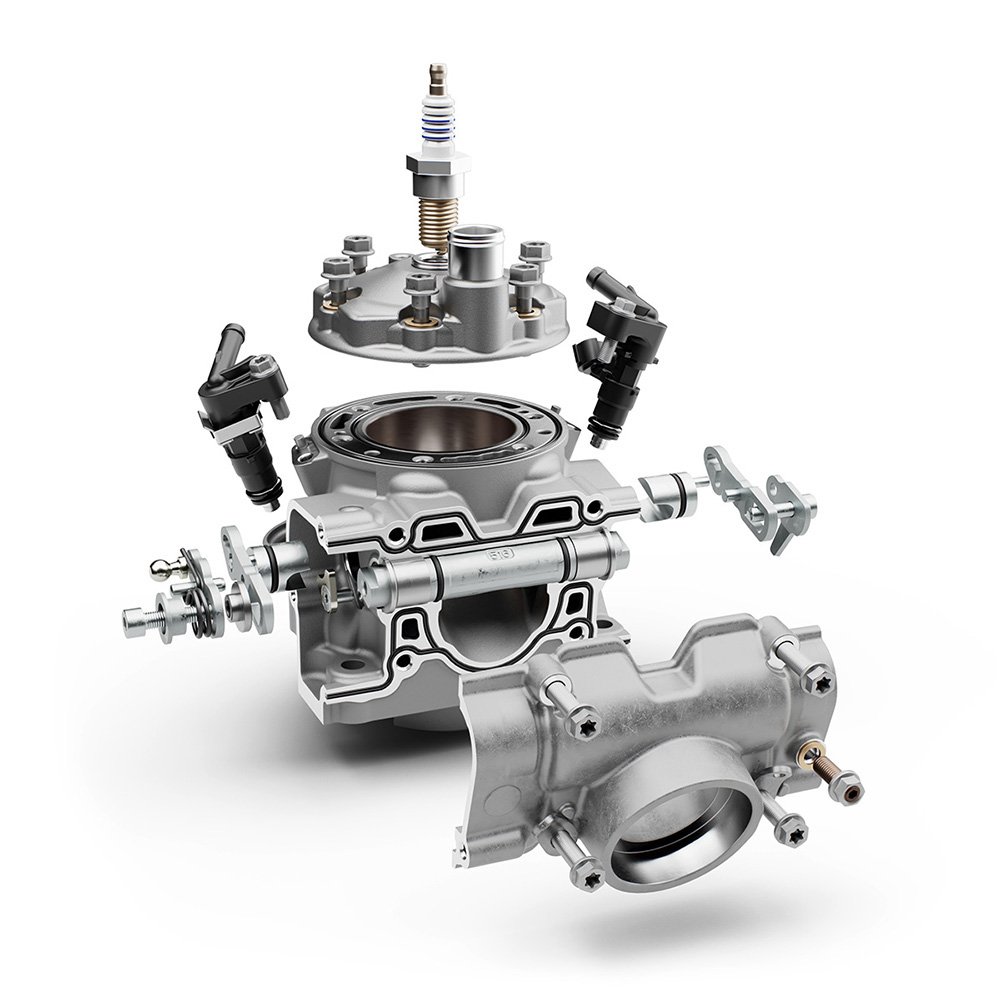

Cylinder and piston

The TE 150 features a cylinder with a 58 mm bore and an innovative power valve design. This allows the lively 150 cc engine to deliver controllable power throughout the RPM range. The piston is designed to perfectly match the contour of the combustion chamber, delivering the highest level of 2-stroke performance. Additionally, the cylinder features injectors mounted at the inlet positions, which deliver the fuel downwards into the transfer port, guaranteeing excellent fuel atomization. This ensures more efficient fuel combustion, reduced fuel consumption and improved emissions. |

Crankcases

Designed for minimal weight, the crankcases on the TE 150 engine feature a thin-wall design. To centralize mass, the shaft arrangements are precisely positioned to harness rotating masses at the ideal center of gravity, while improved sealing is taken care of by the reed block which features optimized carbon fiber reed petals. |

Exhaust

Tailored specifically for each model using an innovative 3D design process, the header pipe on the TE 150 offers an advanced geometry and performance. This allows for improved ground clearance, making the header pipe resistant to impact out on the trail. The muffler also features an aluminium mounting bracket and advanced internal construction for excellent noise damping and weight saving. |

FrameThe proven chromium molybdenum steel frame is refined for 2024. A new shock mounting, which is no longer connected to the main tube, significantly improves the anti-squat behavior of the chassis. With optimized wall thickness in high-stress areas improving reliability, the frame continues to offer advanced geometries and flex characteristics aimed at providing unparalleled rider feedback, energy absorption, and straight-line stability. The frame is complete with a premium metallic blue powder coating with redesigned standard frame protectors offering improved grip in all conditions. Additionally, the redesigned and robust skid plate offers exceptional frame and engine protection.

|

|

|

|

SwingarmThe new hollow die-cast aluminium swingarm is manufactured from a single piece of aluminium using an improved casting process for optimal stiffness and a 190 g weight reduction. In order to optimise and match the flex characteristics of the new frame, a new 22 mm rear axle is fitted. Additionally, the chain guard and chain slider have been completely redesigned for improved durability with the chain guard made with a rounder profile to prevent catching on external objects. |

|

BodyworkAdorned with clean, Swedish-inspired graphics, the bodywork is refined with the ergonomics allowing riders to perform at their best for extended periods of time. Adapted after countless hours of testing, the contact points and surfaces in the rider triangle have been repositioned for 2024 to further improve comfort on the motorcycle. A flatter seat profile offers unrestricted movement with a new, high grip cover ensuring riders stay firmly in place under hard acceleration. Above the side panels, recessed pockets allow for the machine to be lifted and moved, which are particularly beneficial for those competing in extreme enduro events. |

|

FueltankA new and transparent 2.24 gallon (8.5 liter) fuel tank fits neatly within the ergonomic bodywork. The fuel pump is new and features and integrated filter for improved supply, with the fuel line positioned to be less exposed and susceptible to any potential damage. |

|

RadiatorsManufactured from high-strength aluminium, the radiators are designed using Computational Fluid Dynamics (CFD) to channel air in the most effective way. A large centre tube channels coolant through the frame to reduce pressure at this point in the system for a more consistent flow while an internal thermostat further enhances reliability. A new design radiator cap with a bayonet closure ensures a secure fit. |

WP XPLOR front fork

The WP XPLOR 48 front fork is designed specifically for off-road riding. Its open cartridge layout has a spring in each leg with split damping functions. Compression damping is in the left leg and rebound damping is in the right. Adjustment is via easy-to-access clickers (30 clicks) on the top of each fork leg. The standard preload adjusters allow for easier adjustment without the use of tools. The fork's mid-valve piston delivers consistent damping, while the setting allows the fork to operate higher in the stroke for exceptional rider feedback and bottoming resistance. |

WP XACT rear shock

The WP XACT shock provides advanced damping characteristics to the range. New valve seals with reduced hardness offer improved shock feedback. The compact and lightweight shock features a pressure balance inside, ensuring consistent damping and superior rider comfort. Using the same linkage progression found in the Husqvarna Motocross range, the rear end sits low for improved control in extreme enduro conditions. The fully adjustable component delivers 300 mm rear wheel travel, as well as unrivalled traction, feeling and energy absorption. |

Hydraulic brakes

The highest level of quality is guaranteed with the new BRAKTEC braking system, offering the highest level of braking performance while being specifically tailored for enduro riding and delivering a sensitive and modulated feel. GSK wave disks (260 mm disc front and 220 mm rear) complete the high-quality braking package for complete confidence.

|

Hydraulic clutch

The new high quality BRAKTEC clutch system guarantees even wear, reliable and near maintenance-free operation as well as perfect modulation in every condition. Meaning that play is constantly compensated so that the pressure point and function of the clutch remain identical in cold or hot conditions, as well as over time. |

Bodywork

The TE 150 features a bodywork which clearly showcases Husqvarna Motorcycles' progressive approach to offroad motorcycles while the Swedish inspired dark blue and electric yellow graphics create a distinctive look. The ergonomics are specifically tailored to deliver great comfort and control. As a result of extensive testing, the slim contact points make shifting between riding positions easier and allow the rider to flow with movement. The flat seat profile, together with the seat cover texture, deliver superior comfort and control in all conditions.

|

Wheels and tyres

Black high-strength alloy rims by D.I.D are coupled to CNC machined hubs using lightweight spokes and silver anodised aluminium nipples. Fitted to the wheels are Dunlop tires which offer superior grip on a wide variety of terrain. New for 2023, a Dunlop MX33 is mounted on the front and is paired with a Dunlop AT81 on the rear.

|

CNC machined triple clamp

The 22 mm offset black-anodized CNC machined triple clamps offer premium quality and style standard on all Husqvarna enduro models. The triple clamps have been expertly crafted using superior techniques and materials to provide high levels of quality and reliability. A 2-way handlebar adjustment is standard and allows for customisable ergonomics.

|

Map switch

By using the MAP SELECT SWITCH, the engine characteristics can be tailored to modify the power delivery according to rider preference, conditions and terrain. It has two settings which can be toggled on the fly, namely, Map 1, for standard and full power, and Map 2, for softer power and delayed ignition timing for terrain with less traction. |

Throttle body

The TE 150 uses a 39 mm throttle body which regulates the amount of air entering the engine via a butterfly operated by dual throttle cables connected to a handlebar throttle assembly. 2-stroke oil is mixed with the air and enters the engine to lubricate the crankshaft, cylinder and piston. Additionally, a throttle position sensor (TPS) relays airflow data to the ECU which in turn calculates the amount of oil and fuel delivered to the engine while a bypass screw regulates the idling speed and a cold start device opens a bypass providing more air for cold starts. |

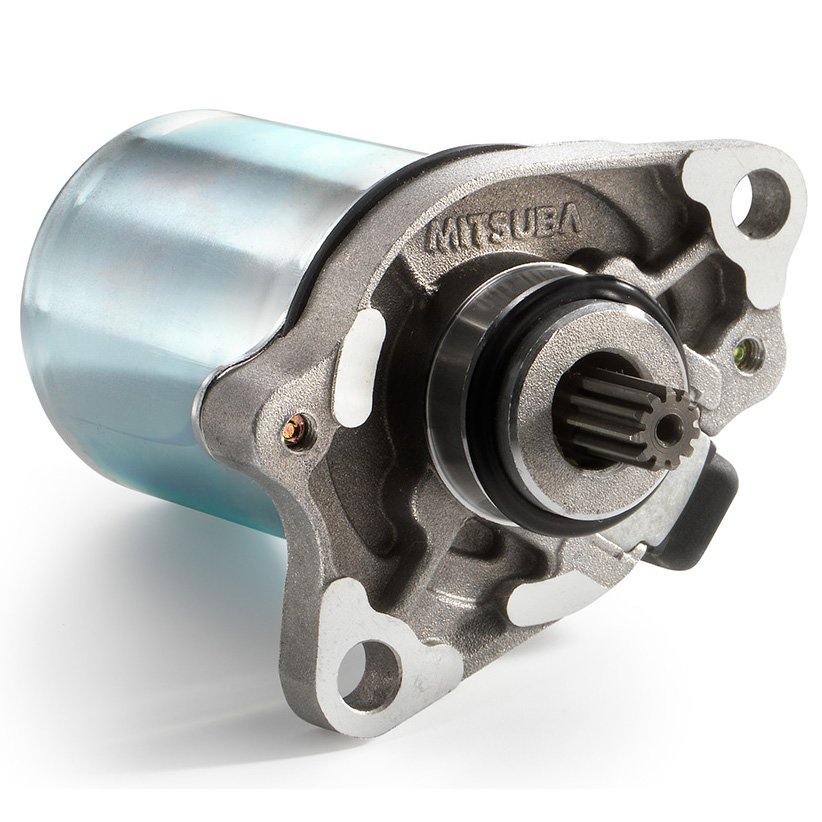

Electric start and wiring harness

All TE models come standard with an electric starter. The system uses a compact and lightweight Li-Ion battery which is 2.2 lb lighter than a conventional battery. With several years of experience of developing and perfecting electric starting, the proven reliability on the Husqvarna enduro range is second to none, ensuring a quick and seamless start in any condition. Additionally, the wiring harness concentrates all needed electrical components into a common area below the seat for easy accessibility.

|

Engine management system

The TE 150 features an electronic control unit (ECU) which is responsible for a number of functions. The unit determines the ignition timing, the amount of fuel and oil injected into the cylinder and additionally, translates the information received from various sensors to adapt values and make corrections for automatic temperature and altitude compensation. This means the engine always runs at the optimum fuel/air mixture at any altitude.

|