- Monday Closed

- Tuesday 09:00AM - 06:00PM

- Wednesday 09:00AM - 06:00PM

- Thursday 09:00AM - 06:00PM

- Friday 09:00AM - 06:00PM

- Saturday 09:00AM - 02:00PM

- Sunday Closed

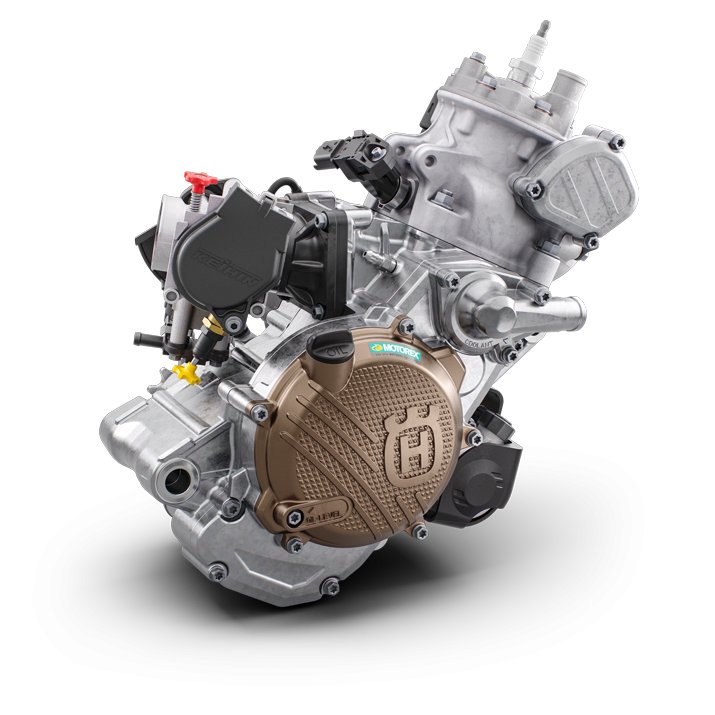

2025 Husqvarna TC 150 HOT FUN 2 STROKE CROSSER LIMITED EDITION HERITAGE MODEL

| New for 2025 is the 2-stroke TC 150. Expertly assembled with the latest offroad technology and premium components, this new addition to the line-up is the perfect choice for riders looking for a little more torque than a traditional 125 cc motocross machine. The TC 150 features an electric start for reliable starting and a highly sophisticated electronic fuel injection system that delivers a smooth spread of controllable power for unbeatable on-track performance. A close-ratio six-speed gearbox, made by Pankl, ensures smooth gear changes and reliability while consistent shifting in all conditions is assured thanks to the uniquely designed gear lever. Ergonomic bodywork wraps around a finely balanced metallic blue chromium molybdenum frame with striking white and blue graphics creating a modern look for the TC 150. |

|

The new and compact 150 cc engine produces class-leading power and torque to suit a wide variety of riders. Mass centralisation inside the engine contributes to the light and agile handling of the machine while a fuel injection system and electronic exhaust control are introduced for the first time on this model. Routine maintenance of the new engine is simplified thanks to the clear markings on the engine covers, which indicate where to check the gearbox oil level, as well as where to drain the coolant from. |

|

The cylinder features a 58 mm bore and as the TC 150 is fuelled via electronic fuel injection (EFI), the traditional powervalve is replaced with an innovative electronic exhaust control system. Using an actuator, the lateral exhaust port and main exhaust port open simultaneously for maximum power delivery. |

|

The lightweight crankshaft improves throttle response and reduces vibration to a minimum. The component is precisely positioned to ensure rotational mass has very little effect on the overall handling of the motorcycle. |

|

High-pressure die cast production processes allow for the crankcases to be manufactured with a thinner wall thickness to keep the overall weight to a minimum and optimise mass centralisation. Symmetrical engine mounts aid handling by contributing to the flex characteristics of the chassis. Internally, all engine components are positioned to achieve an ideal centre of gravity. |

|

|

|

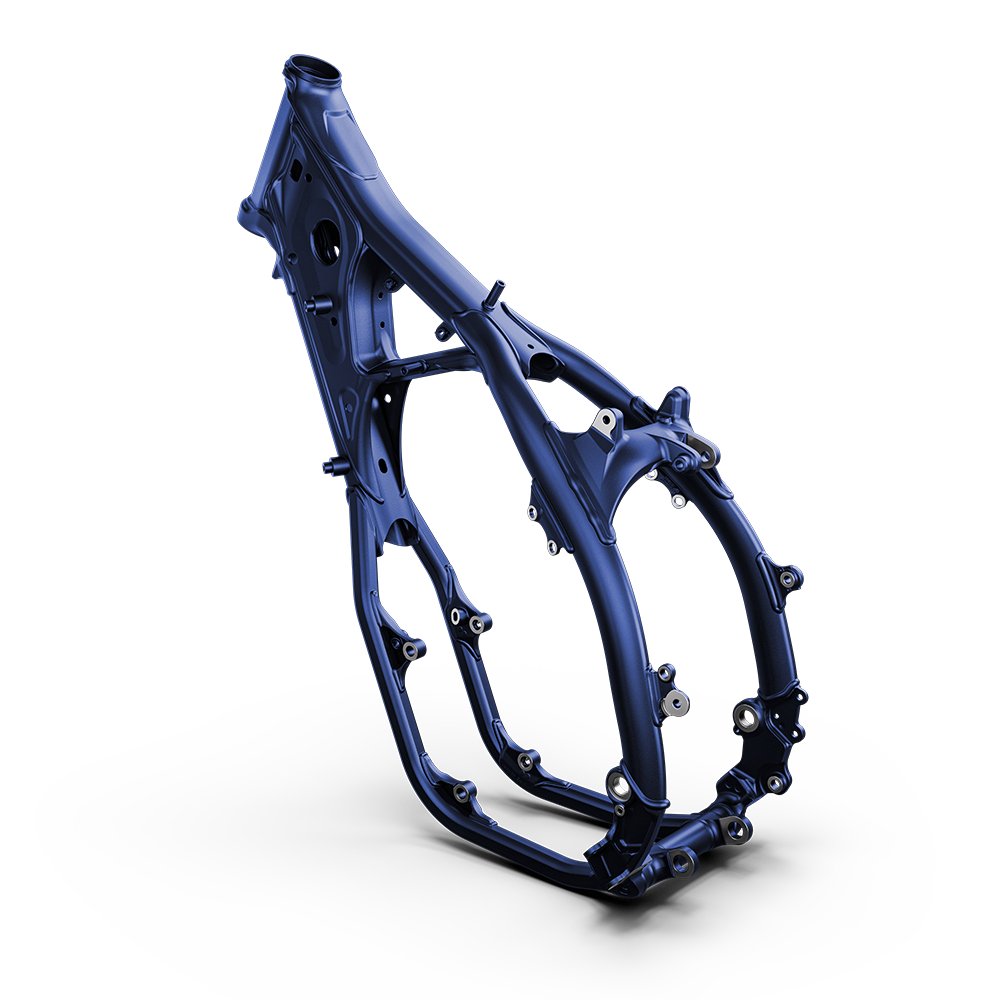

The chromium molybdenum steel frame features optimised wall thickness in all high stress areas for reliability and offers advanced geometries and flex characteristics aimed at providing unparalleled rider feedback, energy absorption, and exceptional straight-line stability. The frame is finished off with a premium metallic blue powder coating with standard frame protectors offering superior protection, durability, and grip in any condition. |

|

Made from 60% polyamide and 40% aluminum, the two-piece subframe ensures exceptional strength and durability at an overall weight of just 3.9 lb (1.8 kg). The lower subframe spars and frame mounts are manufactured from cast aluminum for significantly improved reliability. The upper section of the subframe is made from injection-molded polyamide to enable specific flex characteristics and ensure a lightweight construction. |

|

Working in unison with the frame design and suspension set-up, the CNC-machined triple clamps endure precisely calculated geometry for increased stability. Handlebar flex can be customised with the handlebar clamp, which offers two mounting options - rubber-damped for less vibration, or fixed for enhanced front-end feedback. The upper triple clamp is stiffer to ensure a smoother fork action and plays a vital role in the perfect alignment of the front wheel for superior handling. |

|

Designed as a closed cartridge system, the 48 mm WP XACT-USD forks have a capsulated, adjustable air spring and pressurised oil chamber for smooth action and consistent damping. Oil and air bypasses reduce pressure peaks and in combination with a mid-valve damping system, together with a hydrostop that applies a progressive damping force in the last 40 mm of travel, the forks provide precise feedback to the rider. The settings are easily adjusted via the single air pressure pre-load valve, as well as through easy access click adjusters for compression and rebound. A pump to adjust the air spring pressure is provided with each machine. |

|

|

|

The bodywork has been designed to allow riders to perform at their very best for extended periods of time. Following countless hours of testing and refinements, large contact points and surfaces in the rider triangle enhance comfort, which in turn helps to reduce fatigue. A tall and flat seat offers unrestricted movement with a high grip cover ensuring riders stay firmly in place under hard acceleration. |

|

A strong, one-piece airbox design with an optimised air intake reduces air deformation, ensuring an unrestricted flow of air and maximum filter protection. The Twin Air filter is easily accessed without tools, by simply removing the left side panel for easy maintenance. |

|

|

The highest level of quality is guaranteed as the class leading Brembo brake calipers are made from single-piece aluminium for exceptional strength at the lowest possible weight. Together with a 260 mm front and a 220 mm rear disc, which are designed to prevent mud build-up, superior stopping power and braking confidence is guaranteed in all conditions. A strong rear brake pedal offers exceptional durability for continued braking performance. |

|

Developed between Husqvarna Motorcycles and leading handlebar manufacturer, ProTaper, the exclusive bend offers superior comfort, class-leading strength, and fatigue resistance at the lowest possible weight. |

|

|

|

Assembled with CNC-machined hubs, lightweight spokes, and strong, black-anodised alloy rims by D.I.D, the wheels of the TC 150 offer strength and minimal unsprung weight. New, Dunlop Geomax MX34 Motocross tyres are fitted and feature a proven block-within-a-block design for enhanced control and superior grip on a variety of riding surfaces. |

|

Tailored specifically to the TC 150 engine using an innovative 3D design process, the exhaust pipe ensures maximum power across the rev range. The silencer is easily mounted using an aluminium bracket for strength at the lowest possible weight, with an advanced internal construction ensuring excellent noise damping without sacrificing performance. |

|

Manufactured from high-strength aluminium, the radiators are designed using computational fluid dynamics (CFD) to channel air through them in the most effective way. A large centre tube through the frame reduces pressure at this point in the system for a consistent coolant flow while an internal thermostat further enhances reliability. |

|

|

The electronic fuel injection system on the TC 150 brings many benefits. The ECU constantly analyses the running condition of the engine and guarantees to deliver the perfect air/fuel ratio at all times through the state-of-the-art 39 mm Keihin throttle body. EFI also introduces two different engine maps, which can easily be activated via the handlebar-mounted switch for a personalised riding experience. Map 1 (white) is designed for hard pack while Map 2 (green) is more aggressive and suited to sand and heavier track conditions. Additionally, a redesigned reed valve system improves intake tract sealing and prevents excess fuel building up, which would lead to rich running of the engine in extreme up or downhill sections. |

|

To ensure fast starting in all conditions, the TC 150 features a highly reliable electric start. The system removes the need for a kickstart completely and the additional space created above the engine is used to house the EFI and electronic exhaust control. With the 12.8V 2 Ah Lithium-Ion battery located under the seat and close to the centre of gravity, the handling of the TC 150 is uncompromised. The engine is easily started and stopped via the same handlebar-mounted switch for improved ease of use. |

|

|

The Engine Management System (EMS) is designed to be small, light, and fast at processing data. It incorporates a Rollover Sensor (ROS) that cuts the ignition and shuts off the engine in the event of a severe crash for an additional layer of safety. |

|

The hour meter comes with an integrated fuel level indicator, which is visible on the FI status LED, and warns the rider when the fuel level is getting low. |

|

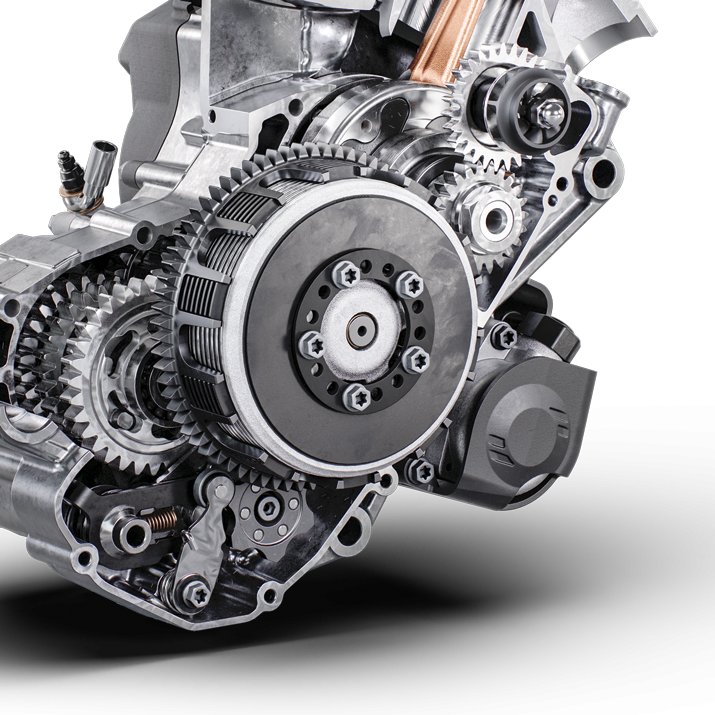

Gearbox

Gearbox DS Clutch

DS Clutch

WP XACT shock absorber

WP XACT shock absorber Swingarm

Swingarm

Hydraulic clutch

Hydraulic clutch

ODI grips

ODI grips Footrests

Footrests

Fuel tank

Fuel tank

Map switch

Map switch

Start/stop switch

Start/stop switch